Blog

Ballistic Shell Construction & Technology

Ballistic helmets

•

Feb 16, 2026

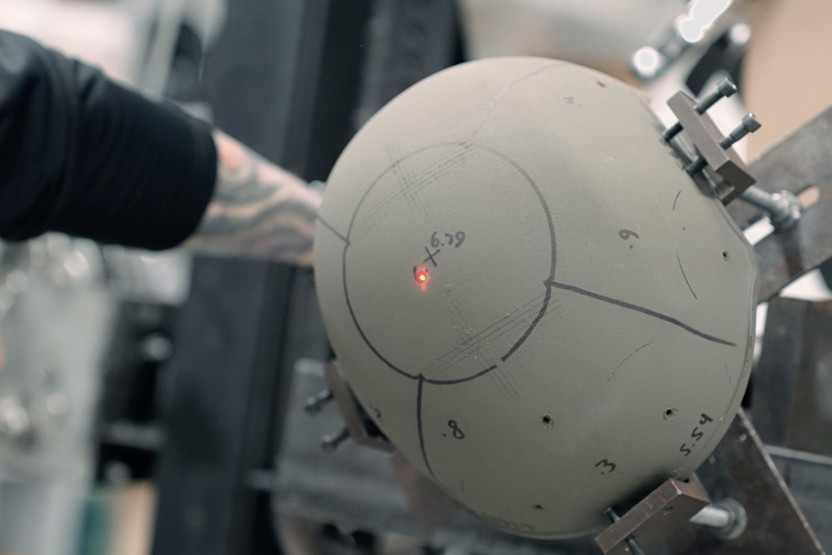

Beyond shape and material, how a helmet’s accessories are mounted to the shell can affect both performance and durability. Traditional helmets often require drilling holes through the shell to bolt on things like chin strap retention systems, side rails, and NVG shrouds. Each bolt that goes through the shell creates a potential weak point since that spot no longer has intact ballistic material and could allow a round or fragment to penetrate easier (approximately 1.5 inches (38 mm) around the hole). To address this, Team Wendy Ceradyne developed “no-thru-hole” shell technology, which means no drilled holes go through the ballistic material but still allows for mechanical attachment ensuring a secure mounting.

In a no-thru-hole helmet, the retention and accessory rails attach without penetrating the shell – for example, using molded-in inserts, surface mounts, adhesives, or clamping mechanisms rather than bolts. Many of Team Wendy’s helmets use this approach. For example, The EPIC® line and new RIFLETECH™ rifle-rated ballistic helmet feature boltless fixtures for retention, suspension, rails, and shroud to ensure consistent performance throughout the helmet.

Why does this matter? Because eliminating through-holes preserves the helmet’s full integrity. In ballistic testing, helmets with no-thru-hole designs show improved resistance with no weak spots from bolts. If you imagine a round striking right where a bolt hole would be – in a traditional helmet, that’s a vulnerable spot. In a seamless shell with no thru-holes, that spot is just as strong as the rest of the helmet. It’s an example of how advances in design are increasing helmet performance beyond just materials.

To illustrate the difference:

From an end-user perspective, you might not immediately notice if a helmet has through-holes or not – but it’s worth asking or checking. Boltless designs (no-thru-hole) are generally superior for the reasons above, and many top-tier helmets now feature this construction.

Even so, not all boltless designs are created equal. Some use adhesives to attach the helmet rails and shroud which ends up being much less secure. Team Wendy’s latest ballistic helmets’ (EPIC Protector, EPIC Specialist, EPIC Responder, RIFLETECH) rails, shroud, and retention system are secured using a patented process to mechanically attach these items without going through the ballistic material keeping the full ballistic integrity intact throughout.